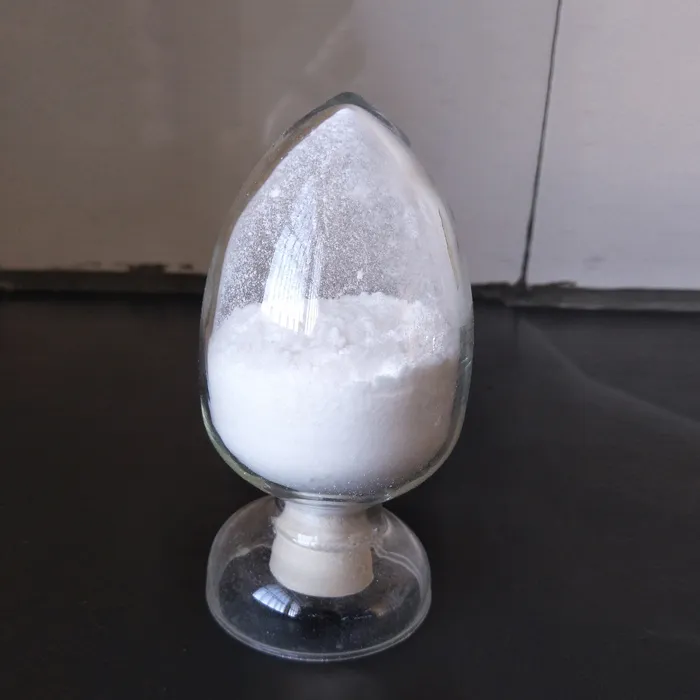

polyacrylamide formation

Links

- pet shop suppliers

- cat sand price

- Innovative Self-Cleaning Litter Box Trays for Hassle-Free Cat Care Solutions

- types of litter

- cat sand bentonite

- kitty litter manufacturers

- bentonite cat sand

- cat tree supplier

- dog grooming suppliers

- cat tower with hammock

- 100% Natural Pine Cat Litter With Strong Water Absorptionl

- cat litter sand wholesale

- types of litter

- bulk pine cat litter

- cat litter sand

- كبيرة الحجم الذاتي تنظيف القمامة

- automatic cat litter box for multiple cats

- medium dog stroller for sale

- cat sand price

- electric cat toilet automatic cleaning

- smart cleaning litter box

- eco clean tofu cat litter

- cat litter cleaner automatic

- buy automatic cat litter box

- types of cat litter

- self filtering cat litter box

- silica cat litter

- cat litter use

- self filtering litter box

- box automatic

- dog grooming suppliers

- automatic cat litter box

- كبيرة الحجم الذاتي تنظيف القمامة

- frische Pinienstreu

- soy cat litter

- auto pulizia scatola lettiera automatica

- automatic cat box for multiple cats

- silica gel litter

- Thùng rác tự làm sạch cho 2 con mèo

- dog bed suppliers

- get cat to use litter robot

- Large Capacity Automatic Cat Litter Box App Control

- how to choose litter for your cat

- pellet pine cat litter

- tofu cat litter original

- Công suất lớn tự động mèo hộp điều khiển ứng dụng

- The Importance of Auto Kitty Litter Cleaners in Families

- Умный мусорный контейнер

- soya cat litter

- automatic kitty litter box for multiple cats

- paint brake drums

- Understanding the Causes and Solutions for Back Drum Brakes Locking Up During Operation

- スターリング2010年型ドラムブレーキの図面とその機構解説

- can we change drum brakes to disc brakes

- 헤비 트럭 브레이크 드럼 리프터 - 안전하고 효율적인 트럭 유지보수

- brake drum vibration

- Exploring the Impact of Modern Technology on Daily Life and Social Interactions in Urban Environments

- Hebei Ningchai how to adjust drum brakes on trailer

- Hebei Ningchai types of brake drums

- OTC 6980 Brake Drum Rotor Puller Tool Overview and Features